Calem Blogs

Blogs of CalemEAM

Featured

How to Configure Boilerplate Work Order Steps by PM Plans

This blog is a tutorial of using PM Plans as default work order steps or safety procedures. Here is one use case we will use in this blog:

- All corrective and PM work orders must have the same safety procedures consisting of the following 7 steps:

- Notify Supervisor/Manager of the affected machine or area

- Apply Lock-Out Tag-Out when needed

- Ensure all energy sources are removed before starting work

- After work Reconnect ALL energy sources and check operation

- Remove all Lock out tag out devices that may have been applied

- Be sure that area is free and clear of all tools that may have been used

- Notify affected dept/supervisor/manager that work is complete

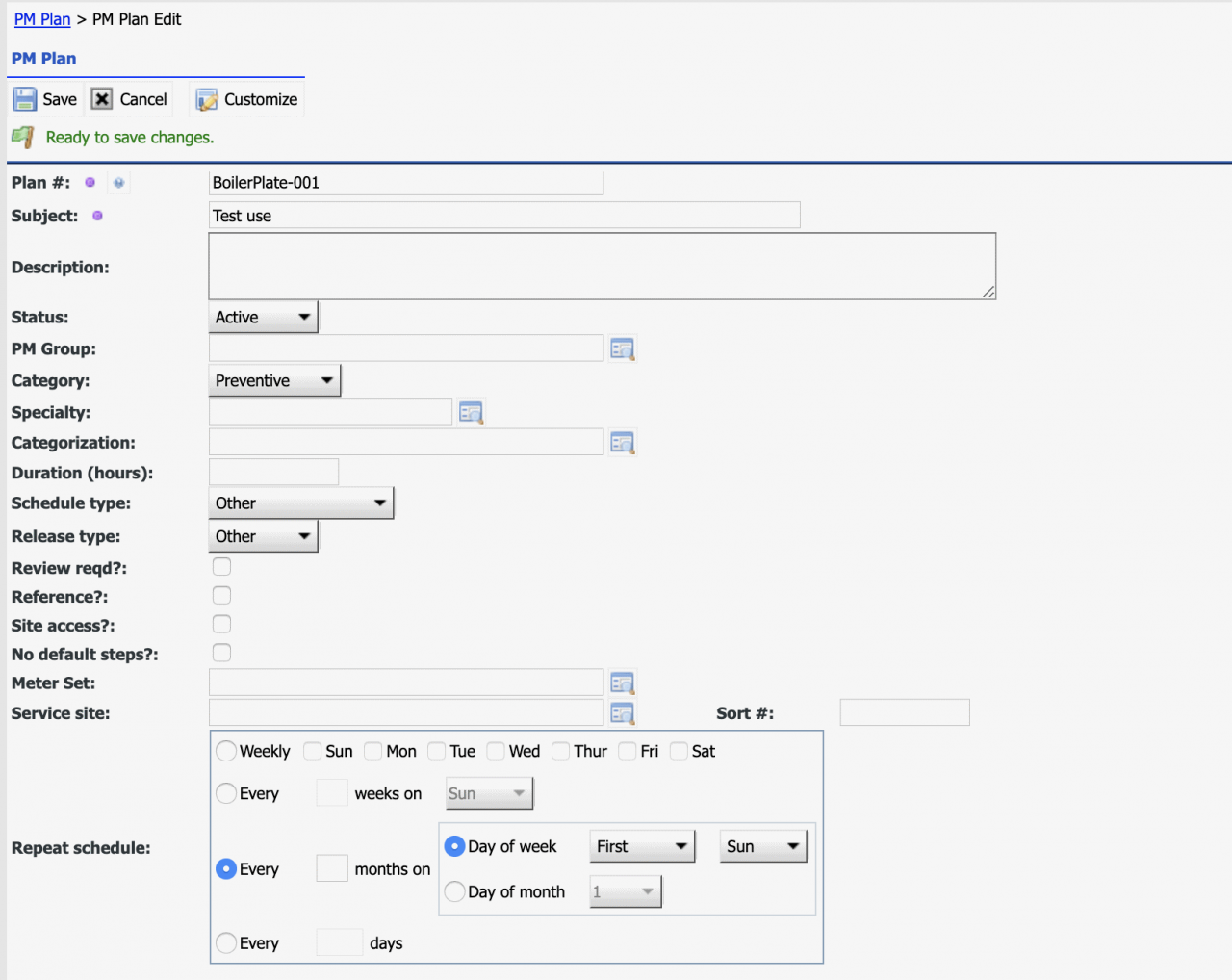

Step 1. Create a PM Plan with Boilerplate Steps/Procedures

Create a PM Plan to hold the safety procedures.

- Menu path: PM module | PM Plan | Click "+" to create a PM Plan (screenshot below) and save it.

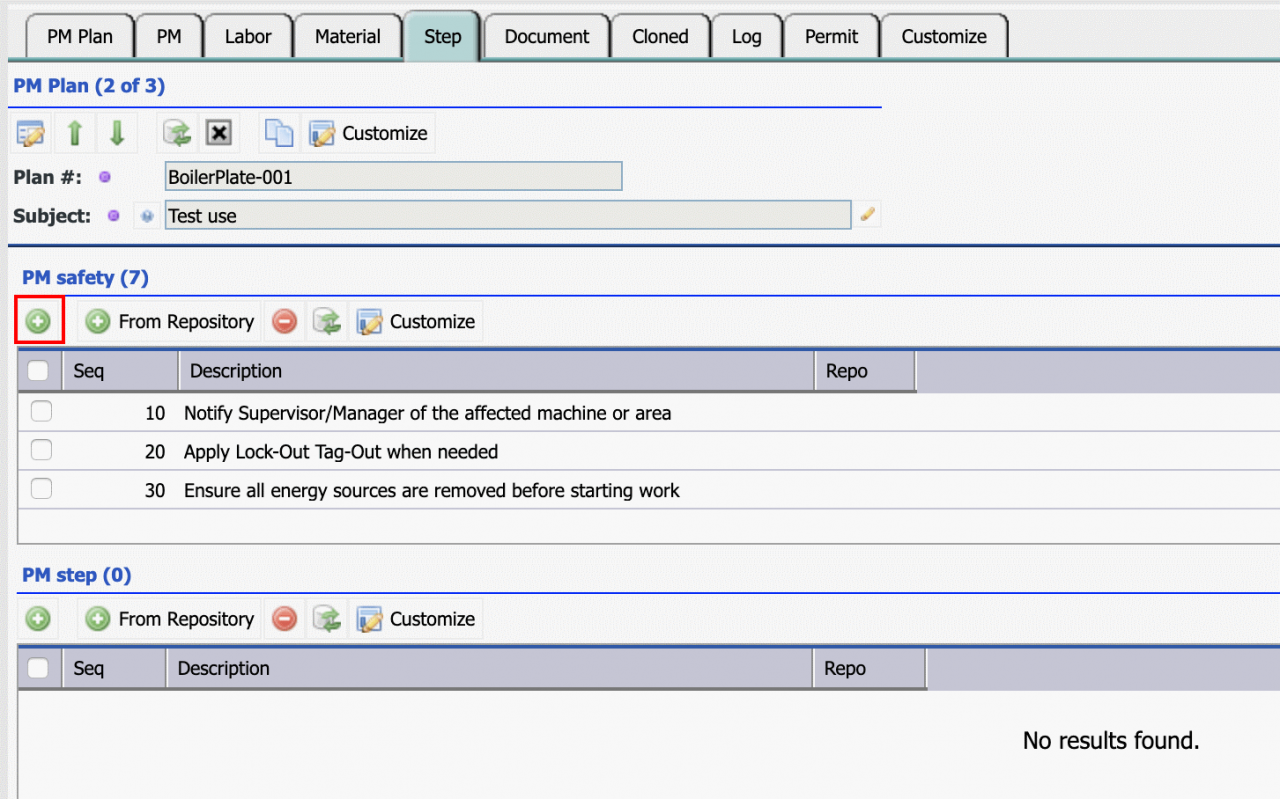

- Go to Step tab of the PM Plan, use the "+" of the PM Safety list to add the 7 steps above.

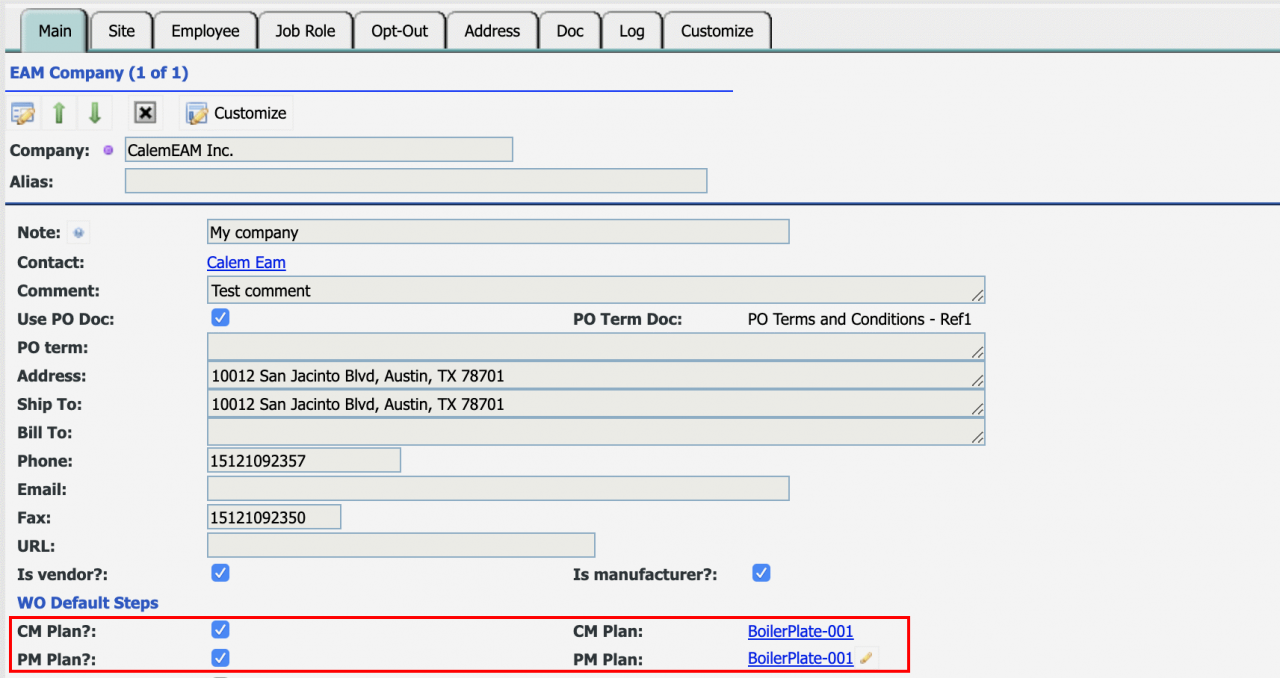

Step 2. Set Default Work Order Safety Procedures

Edit EAM company to set default work order steps/procedures.

- Menu path: Organization module | EAM Company

- Have both CM (corrective maintenance) and PM (preventive maintenance) checkboxes checked, and both CM and PM Plan fields filled with the PM Plan created above.

- The PM Plan's steps and safety procedures are copied to work orders upon creation.

- You may configure a PM Plan for CM default steps/procedures, and a PM Plan for PM default steps/procedures if you wish for CM and PM work orders to have different default steps/procedures.

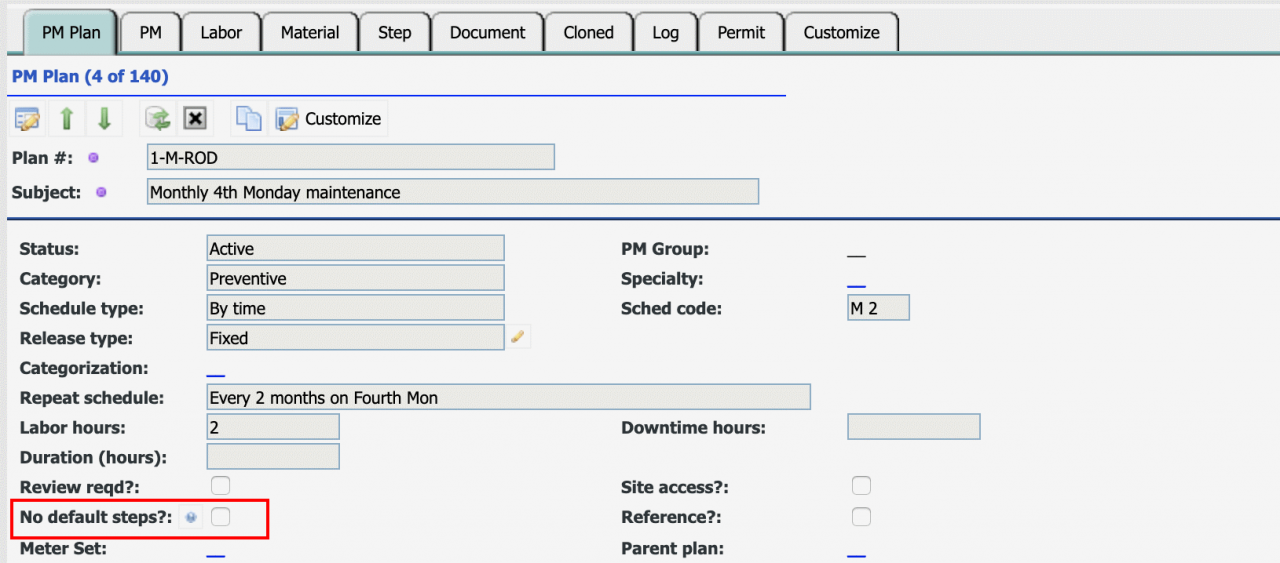

3. Turning Off Boilerplate for PM Plans

The boilerplate steps/procedures are added to PM work orders on top of the steps/procedures from the PM Plan of a PM. Calem provides an option for one to turn off boilerplate steps/procedures at PM Plan form by checking "No Default Step" checkbox.

By accepting you will be accessing a service provided by a third-party external to https://calemeam.com/