Calem Blogs

Streamlining Physical Count by PMs and Work Orders

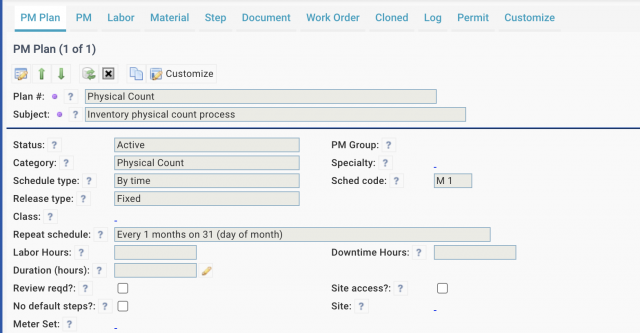

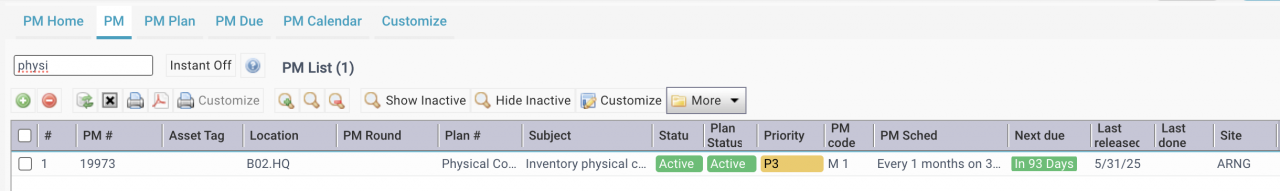

Physical count of inventory can be planned and executed through PMs and work orders in the coming release of Calem R2025b (April 2025). For instance, the screenshots below show a PM Plan for monthly physical count, and a PM of the monthly PM Plan to be executed for physical count.

1. Warehouse Areas

The first step is to divide a warehouse into areas for physical count management - see this blog for detailed discussion.

2. PM Plans and PMs

PM Plans and PMs can be implemented to perform physical count coverage of a warehouse.

- A PM Plan defines schedules to do physical count. For instance, a PM Plan with a monthly schedule is defined to perform physical count every month.

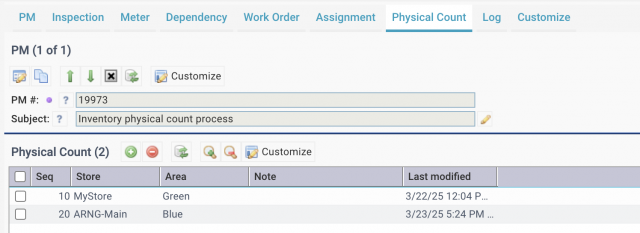

- A PM defines the when (to complete) and where (warehouse areas) to do physical count. For instance, twelve (12) PMs are defined for the PM Plan above. Each PM will be completed by end of a month with some areas of a warehouse being counted.

3. Physical Count Windows

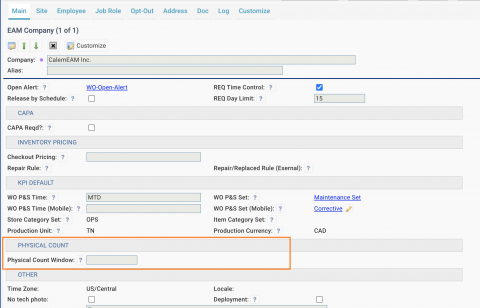

A physical count window defines the number of days to complete a physical count. It is used to measure if a physical count work order is completed in time.

- A default window of 35 days is enabled in Calem.

- The default window can be modified at EAM company.

- A PM can have its own window configured.

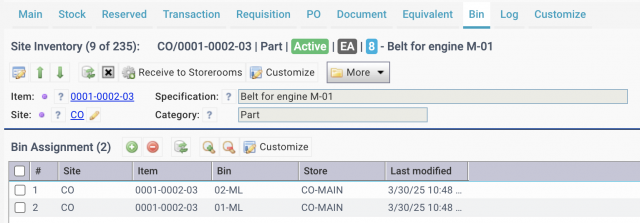

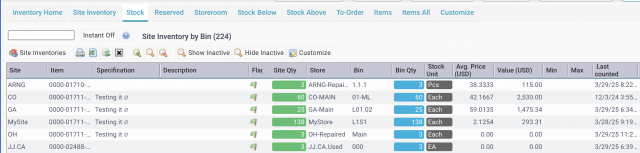

4. Inventory Stock and Bin Assignment

Bin Assignment is not mandatory to start physical counting by PMs. It may be implemented based on business requirements.

Physical count should include current stock and bin assignment. Bin assignment defines where (bins) items are stored. For instance, inventory item 0001-0002-03 is stored in bins 02-ML and 01-ML. A physical count for the item should include any stock as well as the two bins when applicable.

- Bin assignment can be uploaded to Calem by an excel file cm_in_locator_asgn.Bin-Assignment.xls.

- Current stock may be a good place to start with building out the bin assignment. For example, one may export stock from Inventory Home | Stock, and morph into the excel file above (cm_in_locator_asgn.Bin-Assignment.xls) for upload to Calem.

- Physical count of a bin assignment will be skipped for physical count if stocks are present at that bin assignment.

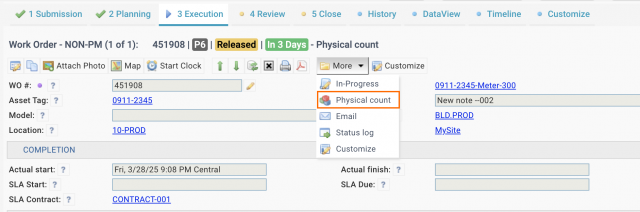

5. Work Orders for Physical Count

Work orders for physical count are created when physical count PMs are generated into work orders by schedules.

- Alternatively, you may create a physical count work order from PM: Work Order | Create WO | Create from PM.

- Create a work order directly will not work since one cannot add areas to count in a work order at this time.

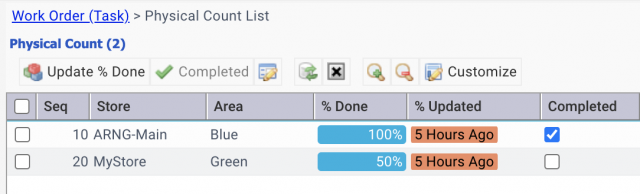

Physical count processes in work orders include data drilldown and integration with physical count transactions. They may be used by warehouse staff to manage physical count efficiently.

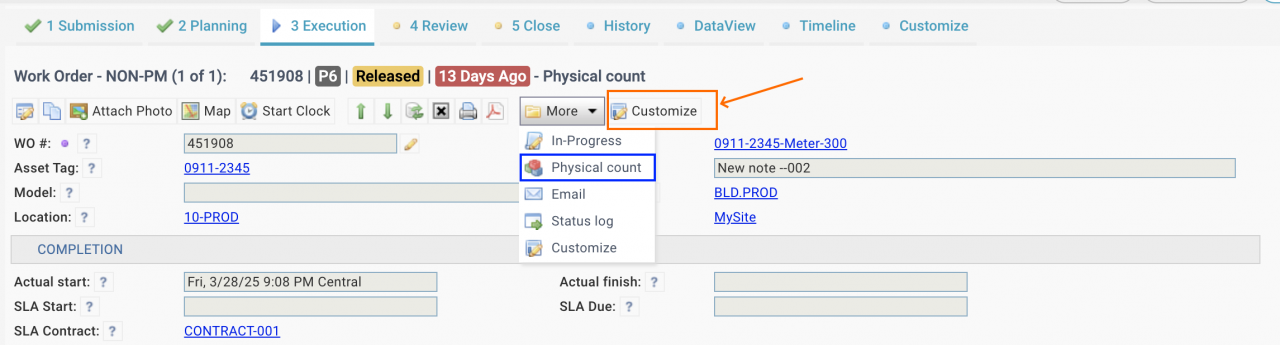

- Use menu "More | Physical Count" to launch the physical count processes.

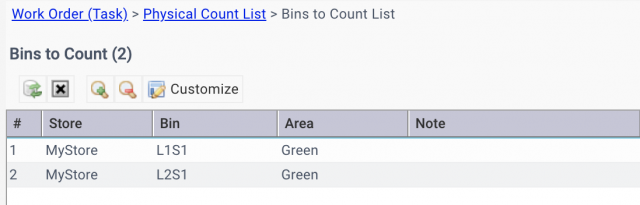

- The list of warehouse areas to be counted are shown.

- Use menu "Update % Done" to calculate the current status of physical count.

- The "Completed" menu may be used when the physical count of an area is done.

- Click an area row in the list to drill down to its bins to be counted.

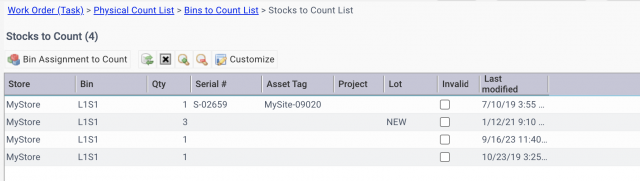

- Click a bin row to drill down to the stock or assignment to be counted for a bin.

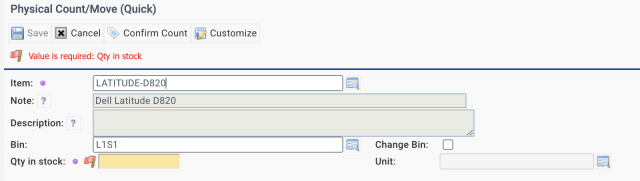

- Click a stock row to launch physical count transaction for that stock row.

- Enter the quantity and click "Save" to complete a count transaction.

- Once a physical count transaction is completed, the "Stocks to Count" list will be refreshed.

- One may continue working this way to finish the counting of all stocks at a bin.

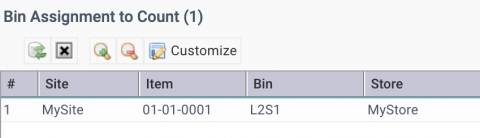

- Click "Bin Assignment to Count" to view bins that need to be counted.

- A bin assignment will not need to be counted if there is stock at that bin.

- Click an assignment row to launch physical count transaction like stocks above.

6. Calem Mobile

The work order processes for physical count are available in Calem Mobile.

7. "Physical Count" in More Dropdown of Work Order

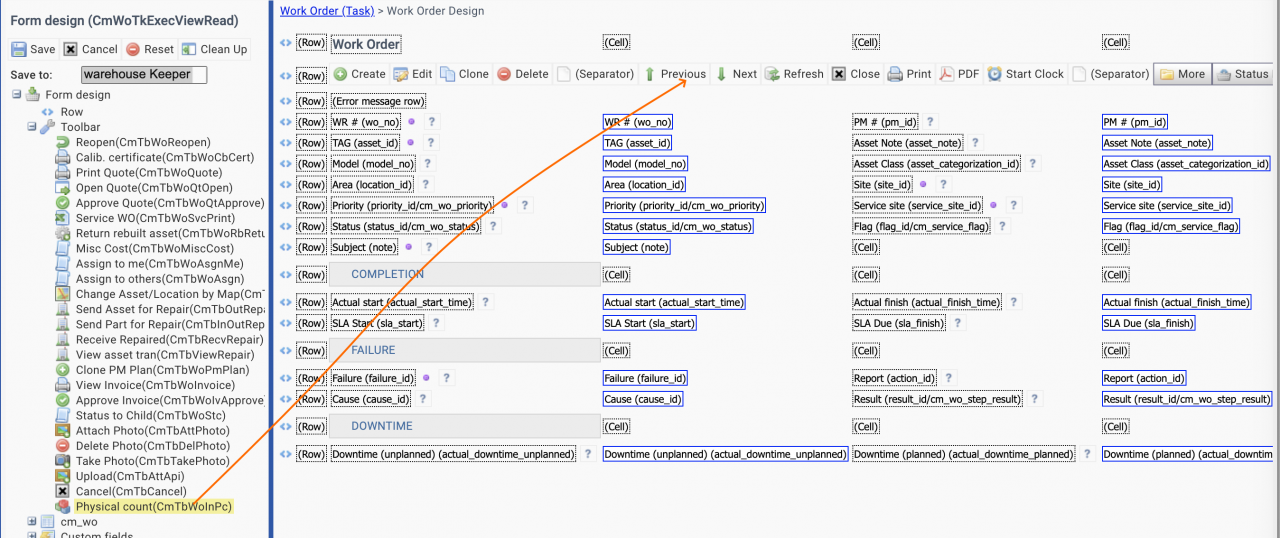

The "Physical Count" menu is available in the "More" dropdown menu from the "Execution" and "Planning" tabs of work order form for work orders with category of "Physical Count". If the menu does not show it is because the menu has been customized. Here are the steps to add "Physical Count" menu.

- Select a group to do the customization. For instance, select "Custom System" group to add the menu for all users.

- Then, go to Work Order| Open WO | select a WO to open its form

- Go to the "Execution" tab, customize it.

- In the designer screen, drag "Physical Count" menu from left panel and drop to the menu bar in the right panel. Save the customization. See this blog for more info about form customization.

Additional Resources

- Physical Count Planning: Storeroom Areas

- How to Do Access Control by Roles (Group Design for Module Access)

- How to Barcode with Phone/Pad in Calem

- Calem Barcode for Physical Count

- Calem Barcode with Windows 10 Touch PC

- How to Implement PM Checklist

- Inventory Training

- User Guide and Admin Guide (customer account required)

- Calem Enterprise Training Site

- Calem Enterprise Blogs

- Calem Enterprise demo

By accepting you will be accessing a service provided by a third-party external to https://calemeam.com/