Calem Blogs

Purchase Automation by Min/Max and PMs

Purchase process automation includes the following steps:

- A. Use Min/Max to control inventory stock levels.

- B. Create requisitions when inventory stock falls below the minimum stock quantities.

- C. Route requisitions to supervisors for approval

- D. Create a PO when a requisition is approved

- E. Email a PO print in PDF format to vendor when a PO is approved

1. Ordering by Min/Max Automatically

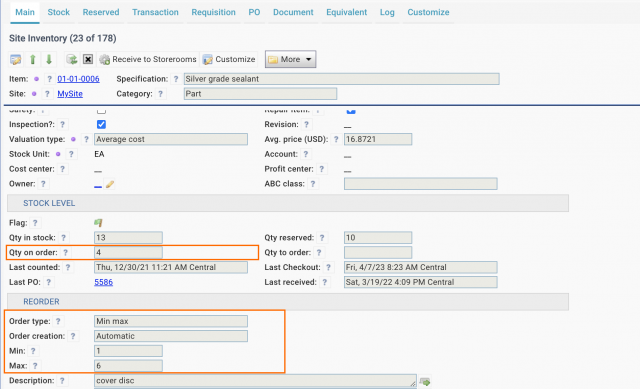

Min/Max can be configured at site inventory for automating the creation of requisitions when stock levels fall below minimum stock levels.

- Set Min/Max stock levels

- Set Order type to Min/Max

- Set Order creation to Automatic

- Requisitions are generated when stock levels fall below minimum levels

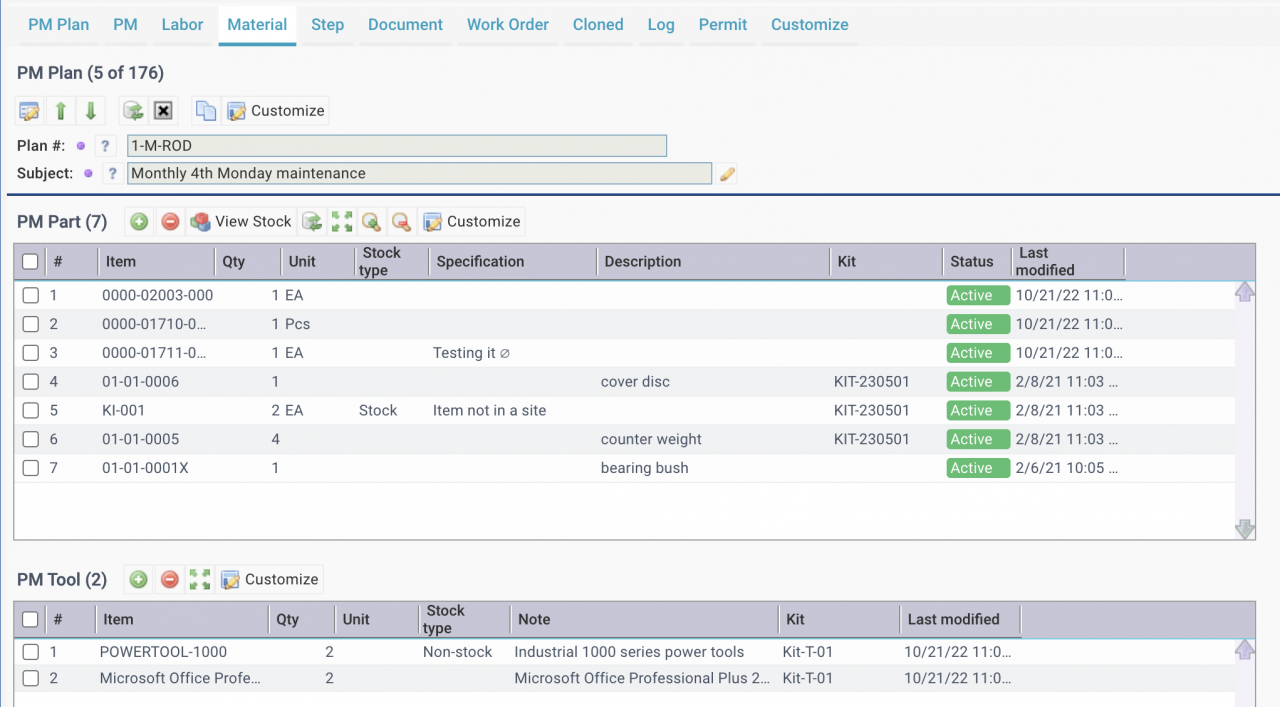

2. PM Reservation and Part Ordering

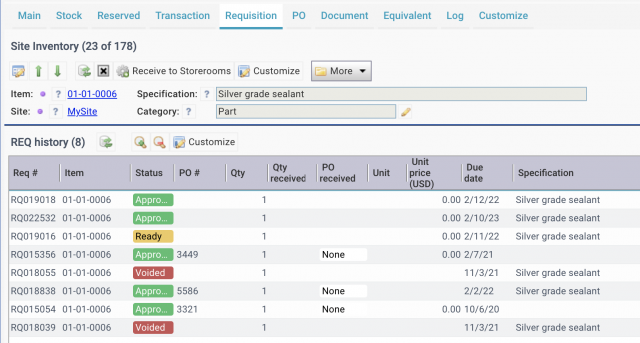

Part requirements may be defined at PM Plans. PM Parts are counted as reserved when PMs are generated into work orders and work orders are released. There are options to trigger requisitions based on PM reservation

- Option 1. PM reservation contributes to triggering requisition generation. If current stock level minus reservation is less than minimum stock level for a part, a requisition is generated. Its goal is to allow PMs to be completed without waiting for parts.

- Option 2. PM reservation does not trigger requisition generation. A requisition is only generated when the current stock level is less than the minimum stock level. Its goal is to minimize stocking parts.

- Option 1 is configured out of the box in Calem. Option 2 may be selected to minimize inventory stock and defer ordering for PMs. Customers of Calem Cloud may contact support to enable option2. See Admin Guide for more info (customer accounts required).

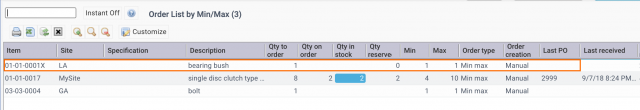

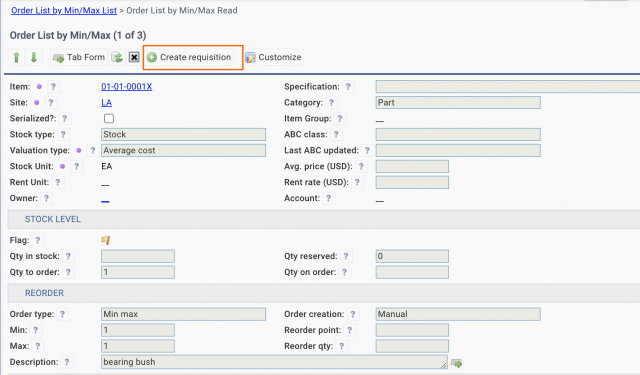

3. Ordering by Min/Max Manually

Manual ordering can be enabled based on Min/Max stock levels. Calem will not generate requisitions in this case. Instead, inventory staff review items to order and manually create requisitions.

- Set Min/Max stock levels

- Set Order type to Min/Max

- Set Order creation to Manual

- Inventory staff review orders to generate from reports:

- Inventory | Report | Order List by Min/Max

- Inventory | Report | Order List by Min/Max with Vendors

- Review an order row and manually create a requisition by menu "

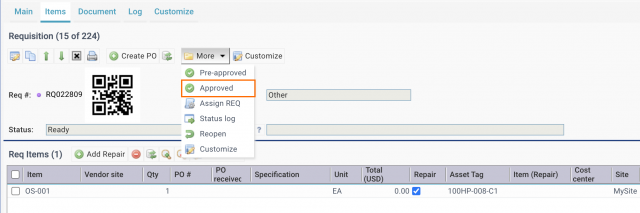

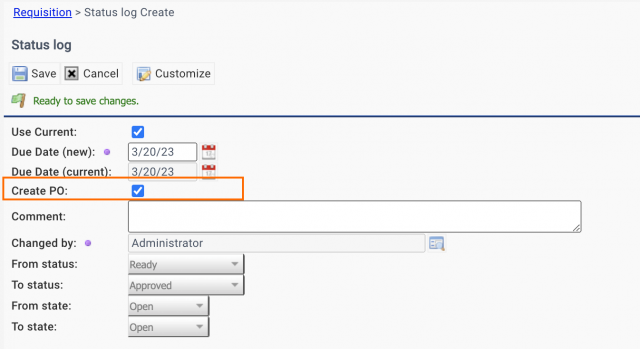

4. Generate a PO at REQ Approval

The screenshot below shows the "Approved" menu to approve a REQ. The checkbox "Create PO" can be checked to generate a PO upon approval of the REQ.

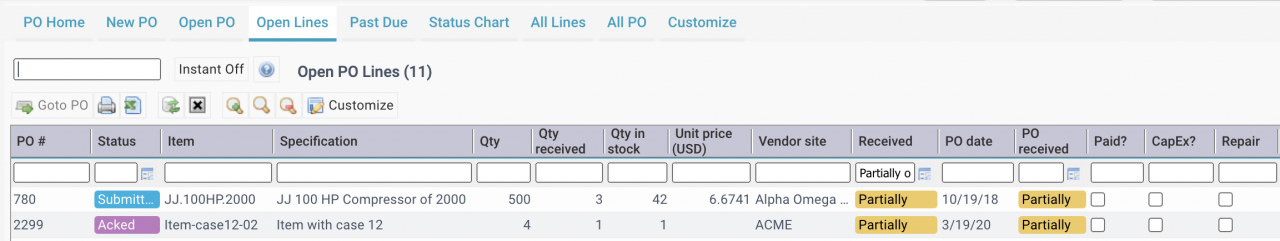

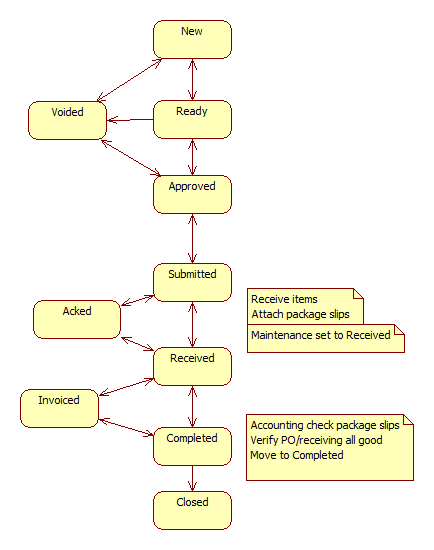

5. Purchase Process Coordination

Maintenance and accounting teams may work together to complete POs:

- Maintenance team receives a PO, attach package slips, change a PO's status to "Received" when a PO is fully received.

- Accounting team reviews POs with receipts (Purchase Home | Open PO Lines | POs of partial/fully receipts).

- Partial or full payment may be made to vendors depending on PO terms.

- Accounting team changes a PO's status to "Completed" when invoices are processed for the PO.

Additional resources

By accepting you will be accessing a service provided by a third-party external to https://calemeam.com/